The new

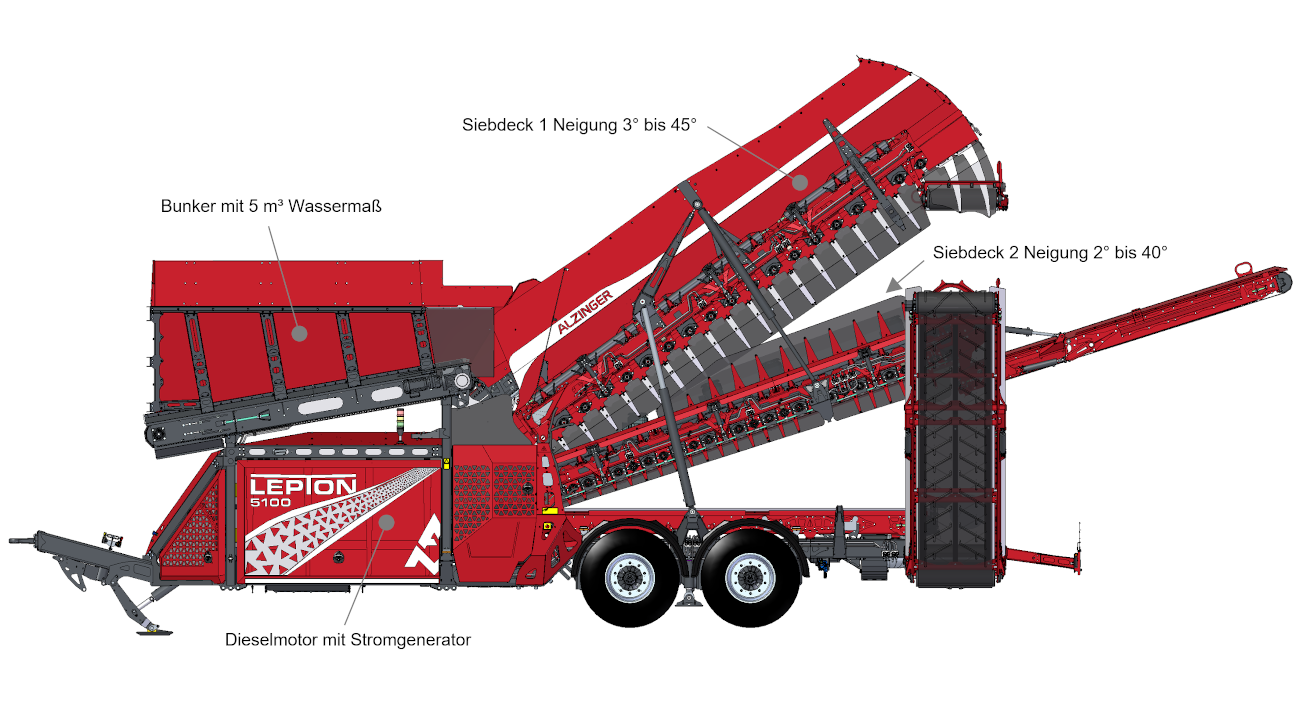

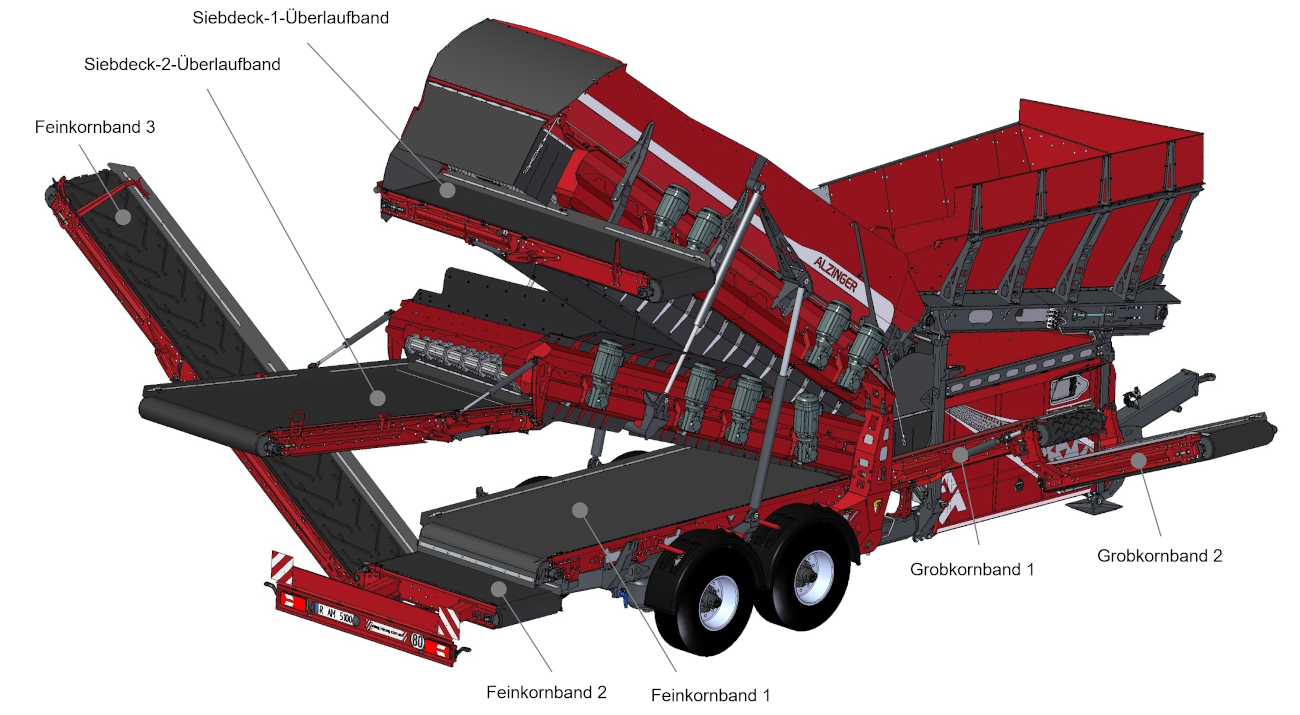

The Lepton 5100 is a mobile disc screening machine with 5 grain fractions and 2 screening decks, used especially for wood containing biomass. Following materials are processed:

- compost

- organic waste

- humus / turf / organic soil

- wood chips

Considering the application field “organic waste”, the material is separated in the following 5 grain fractions:

- fine grain (compost)

- medium grain (for further processing)

- screening deck 1 overflow (commonly plastic foil and bulky pieces)

- coarse grain 1 (spherical particles like stones)

- coarse grain 2 (coarse pieces of wood)

Specification:

- drive:

- 100 kW FPT NEF45 diesel engine

- electric generator ACG 80 kW

- electric motors for all screen rolls and conveyor belts

- 4x 7 kW motor / screening deck

- 7.5 kW hydraulic unit

- central lubrication 24 V with 4 l tank

- dimensions:

- 18 t total weight

- 80 km / h speed permit

- 11.97 m total transport length

- 3.98 m total transport height

- 2.53 m total transport width

- no special permit required

- screening decks:

- screening deck 1: 3° - 40° slope, 7.4 m², 19 screening rolls, 17 mm – 34 mm adjustable spacing, 0 – 313 rpm speed

- screening deck 2: 2° - 35° slope, 7.4 m², 29 screening rolls, 6.5 mm – 13 mm adjustable spacing, 0 – 313 rpm speed

- custom built spacing possible

- central lubrication of screening rolls

- cleaning mechanism of screening rolls with 3 segments per screening deck

- axles:

- 9-ton axles with air pressure drum brakes

- leveling with 2 support legs

- antilock braking system

- bunker:

- volume 5 m³

- conveyor belt speed adjustable from 1 m / min – 8 m / min

- conveyor belts:

- 5 grain fractions incl. shape dependent separation (wood / stone)

- maintenance free drum motors

- rubber conveyor belts with standard dimensions

- slope adjustable

- central lubrication of flange bearings

Lepton 5100 media center

Mechanical engineering

We are supplier for sheet metal components. Primarily, we produce components by our Trumpf production lines Trulaser 5030 and TruBend 5230.

With our automated sheet metal storage TruStore, large number of pieces can be processed economically and highly automated. (Imagemovie).

Please send inquiries to Herrn Martin Alzinger. Ideally you attach 3D-CAD files.

- 2D-CNC laser cutting

- using TruLaser 5030

- different metals processable

- typically used: S355, S700, Hardox 500, V2A, aluminum

- sheet metal thickness from 0.5 mm to 25 mm

- format: 3m x 1.5 m or smaller

- automated storage TurStore für 20 sheet metal packages

- CNC sheet metal bending

- using TruBend 5230

- maximum bending lengths: 4 m

- sheet metal thickness from 0.5 mm to 20 mm

- 3D-CAD supported bending software

- dies from 8 mm to 120 mm width

- punches with R1 and R4 without and with offset

Product development

We develop our products using latest software solutions like 3D-CAD, FEM and multibody dynamics.

Our focus is on the development of efficient, high-performance, economical and long-life vehicels. In the field of sheet metal manufacturing, we use 3D-CAD cut and bending simulations. Our designs are simulated and optimized by the structural simulation software Ansys Workbench.

Due to reasons of mobility and efficiency, special focus is on light weight design and electric drives.

Contact

Richard Alzinger

managing director

focus on technology and sales

Phone: +49 170 333 602 5

E-Mail: richard@alzinger-maschinenbau.de

Martin Alzinger

managing director

focus on technology, software development and accounting

Phone: +49 170 312 853 3

E-Mail: martin@alzinger-maschinenbau.de

Dr. Johannes Dallmeier

head of product development

Phone: +49 170 472 67 31

E-Mail: johannes.dallmeier@alzinger-maschinenbau.de

Kathrin Alzinger

purchase of technical equipment

Phone: +49 170 966 526 3

E-Mail: kathrin@alzinger-maschinenbau.de

Company

The Alzinger Maschinenbau GmbH was founded in 2018 by Richard and Martin Alzinger.

It develops and produces the mobile disc screening machine for wood containing biomass. With the Lepton 5100, the company offers a 5-fraction disc screener with 2 screening decks and up to 400 m³ / h output.

The founders Richard and Martin possess a professional experience since many years. Richard work since his apprenticeship in the field of sugar-beet harvesting technology. His aim till now is the development of reliable machines to ensure the success of the customer. Additionally, Richard is one of the founders of Albach Maschinenbau. Martin contributed to the success of Albach from the beginning. His focus was on technology and software. In his position as head of after sales service for many years, he received a lot of professional and international experience.

Locations

Alzinger Maschinenbau GmbH Germany

you will find us at Schierling, Am Gewerbering 14

foreign distributor:

ROPA France - Golancourt

280 rue du Château • F-60640 Golancourt